- Home

- ›

- Valuable Information

How do you install round ducts?

Have you ever seen intalling round ducts?

This video was taken at Ikeda Thermal Industry Co., Ltd.

You may immediately understand how to install round ducts if you view the video.

It will be beneficial for you to watch the video in order to see the difference in installation between rectangular ducts and round ducts in work involving high places.

【Quote from Ikeda Thermal Industry Co., Ltd.】

- ・Start here for spiral duct information

- ・Band information....

Perforated Band. Start here for bands

For D-band

For U-band

For Split band

What is the cutting method for a round duct?

This time we will introduce a method of cutting round ducts using a disc grinder. With this method, draw a line with a pen or pencil at the location of the desired length of the duct body, and then cut the duct with the blade of the disc grinder along the line of rotation.

The cutting speed can be increased dramatically with this method.

(Caution: Be sure to wear protective safety glasses when cutting because dust from the duct may cause an injury.)

【Quote from Yuwa Reidanbou Co.,Ltd.】

- ・Start here for spiral duct information

Method to determine the air volume that passes through the duct

Do you know how the air volume passing through the duct has been calculated?

Actually, the methods of calculation are different, depending on the applications and purposes. There are three ways: a logical calculation formula, a calculation formula provided in the law, and a calculation formula derived from experience.

- Example of a logical calculation formula

- Indoor air conditioning: Cooling load = air volume x temperature difference (indoor temperature – air supply temperature)

- Example of calculation formula provided in the law

- Smoke exhaust: 1m³/min. per unit area

- Example of calculation formula based on the experience of artisans

- Ventilation: Indoor volume per hour (number of times of air changes at m³ [air change rate])

For example, the air change rate for a lavatory is 10 to 15 times.

How about it?

We manufacture and sell round ducts as well. Please see here by all means.

Reference book: "Duct guide book" Institute : The National duct industrial group association.

How will the duct size be determined

Air conditioning ducts come in different types and sizes. How will the duct size be determined?

This time we will introduce a way to determine the duct size.

*The most popular method is called the constant pressure method or equal friction method.

- Step1Calculating duct air volume (m³/h)

- Step2Calculating the air velocity inside the duct (generally about 5 to 10 m/s)

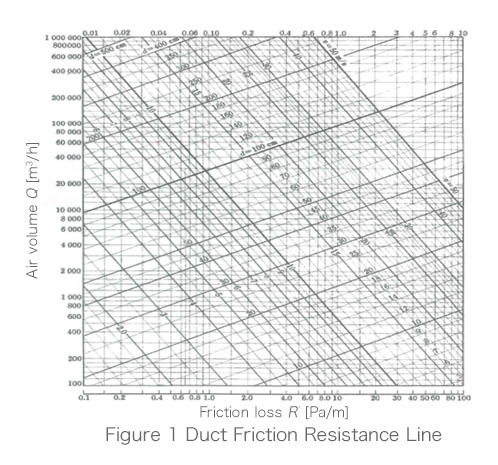

- Step3The size of the round duct (cm Φ) will be determined for total air volume, depending on the intersection of air volume (left) and air velocity (downward-sloping oblique line) in the illustration. Also, if you draw a straight line right below the intersection, you can find the friction loss value per meter of duct (Pa/m).

This is called the reference loss value. In most cases, the reference loss value is about 1 Pa/m. - Step4As shown below, each duct size (cm Φ) will be calculated by the intersection of air volume at each part (left) and this reference loss line (vertical perpendicular line).

- Step5Round duct size

How about it?

We manufacture and sell round ducts as well. Please see here by all means.

Reference book: "Duct guide book" Institute : The National duct industrial group association.

Method to convert from a rectangular duct to a round duct

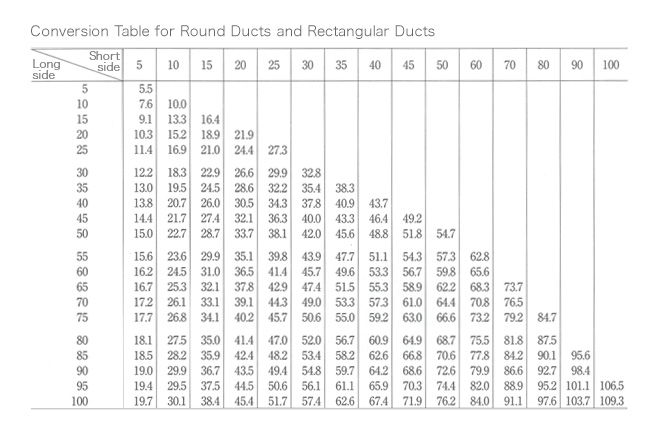

Are you curious about what rectangular (square) duct size is equal to a round (circular) duct size?

On such occasions, the conversion table below is quite useful

The friction loss with the same air velocity is in the order of circle < square < rectangle (though it may vary with the circumference).

The size closer to a square may have a smaller friction loss and be more economical. (If you cannot find the suitable size in the table, please contact us.)

Features of a round duct

Seams in a spiral shape provide greater strength.

The seams in a spiral shape are a unique feature of spiral ducts. This creates strong reinforcement, greater flexibility, and the added strength to make it possible to use even for high speed ducts and smoke exhaust ducts.

Because of superior workability, the connection to a variety of different connectors is easy.

Because high accuracy is guaranteed in plant production, no special skill is required for the connection to connectors.

Friction will cause neither loss nor leakage, and the duct offers superior economy.

Since the inner surface is finished beautifully, there will be no loss or leakage from friction. Customers will save transportation, installation, and accessory material costs because the product is standardized and light in weight.

How about it?

We handle many spiral ducts as described above.

Please see here by all means.